In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

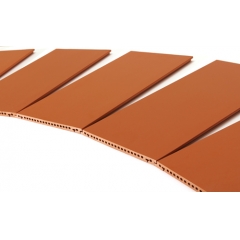

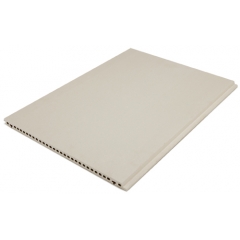

More| *Model No.: | F301801 |

|---|---|

| *Place Of Origin: | Fujian, China |

| *Material: | Natural Clay |

| *Size: | 300*1200*18mm |

| *Color: | White |

| *Packaging Details: | 31kgs/sqm |

| *Payment Terms: | L/C, T/T, Western Union |

| *Port: | Xiamen |

| *Delivery Time: | 20 days after receiving deposit |

| *Certification: | CE, ISO9001:2008 |

About LOPO Terracotta Panel:

LOPO Terracotta panel use natural clay as the main raw material, add a small amount of other ingredients like quartz, pumice, feldspar and pigments etc., then through high-pressure extrusion molding, low-temperature drying and 1200℃ high temperature firing, finally comes out the terracotta panel.

Exterior Wall Terracotta Panel is completely environmentally-friendly, even the waste material can be recycled because it is made of raw material natural clay and firing production process.

18mm Terracotta Panel is eco-friendly, no radiation, color gentile and without light pollution. Besides that, terracotta panel has a rich optional color for choice, which meets the color selection requirements of architects and owners. The double hollow structure design not only reduce the weight of terracotta panel, but also improve the ventilation, noise reduction and thermal insulation performance of terracotta panel.

Specification:

Model No.: |

F301801 | Brand Name: | LOPO |

Material: |

Natural Clay | Supplying Ability: | 2500sqm/day |

Size(W*L*T): |

300*1200*18mm | MOQ. Quantity: | 1x20'GP |

Color: |

White | Packaging: | Wooden crate |

Weight: |

31kgs/sqm | Loading: | 619.20sqm/20'GP |

Certification: |

CE, ISO9001:2008 | Lead Time: | 20 days after receiving deposit |

Customized Design: |

Available | Payment Term: | L/C, T/T, Western Union |

Regular Terracotta Products:

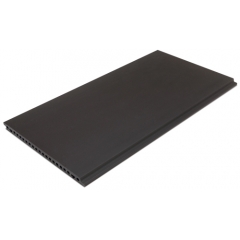

| Regular Product: | Color: White/Yellow/Grey/Red/Brown Surface Treatment: Flat/Grooved/Sanded/Glazed/Linear/Wood/Corrugated |

| Dry Hanging Terracotta Panel: | Length: 250mm-1500mm Width: 150mm-600mm Thickness: 18mm/30mm |

| Small Size Terracotta Panel: | Width: 100mm-200mm Thickness: 10mm-15mm |

| Lightweight Terracotta Panel: | Length: 250-1500mm Width: 150mm-600mm Thickness: 10mm-15mm |

| Note: |

Customized design is welcome! Just send us your design or sample. |

Terracotta Facade Panel Technical Data Sheet:

Terracotta Panel Technical Data Sheet |

||||

NO. |

Contents |

(300*600*18mm) Terracotta Panel |

China N. S. GB/T4100-2006 |

EN14411 standard |

1 |

Water Absorption |

5.4% |

(II) 6-10% |

(II) 6-10% |

2 |

Net Weight |

31kg/m2 |

No value |

No value |

3 |

Breaking Strength |

3475N |

≥ 900N |

≥ 750N |

4 |

Frost Resistance |

No crack under -60 centigrade |

Tested value of the report |

Tested value of the report |

5 |

Modulus of Rupture |

Avg. 13.1Mpa, min 11.8Mpa |

Avg. ≥ 9Mpa, single value≥ 8Mpa |

Avg. ≥ 9Mpa, single value≥ 8Mpa |

6 |

Earthquake Resistance |

Over 8 degree |

No value |

No |

7 |

Test Under Simulated Wind Load |

No breakage under 10Kpa |

No value |

No |

8 |

Sound Insulation |

Noise reduction by over 8dB |

7-10dB |

No |

9 |

Wind Pressure |

9kPa |

Tested value of the report |

Tested value of the report |

10 |

Heat Conductivity |

0.32 w/m.k |

No value |

No |

11 |

Fire Resistance |

level A1 |

No value |

No |

12 |

Resistance to Acid and Alkali |

Level UA |

Tested value of the report |

No |

13 |

Radioactivity |

Class-A decorative material |

No value |

No |

14 |

Right Angle |

0.1%- -0.2% |

Within ±1% |

No |

15 |

Size Error |

300L: 0.1%- -0.4% 600L: 0.2%- -0.5% |

Within±2% , max is within ±2mm, |

No |

16 |

Thickness Error |

Within ±4.5% |

Within ±10% |

No |

17 |

Diagonal Line |

-0.5 ~ +0.2 Max 1.0mm |

Within ±2% |

No |

Terracotta Facade Panel Feature and Benefits:

1. Natural terracotta clay materials, eco-friendly

2. Rich color and surface design available

3. Hollow structure and light weight design

4. No-static and no-radiation

5. Never fade, strong and durable

6. Convenient fixing installation, safe and reliable

7. Wind and earthquake resistance

8. Anti-fire, anti-freeze, heat preservation and sound insulation

9. Self-cleaning, easy maintenance

LOPO China Production Ability:

1. Domestic longest roller kiln(260-meter) with 428 firing units;

2. 80,000 square meters open stockyard with the daily reserve of natural clay raw materials amounts to 300,000 tons;

3. The new workshops and production lines under construction;

4. The semi-production indoor repository with storage capacity of 150,000 tons;

5. The automatic production line with the processing capacity of shaping, cutting and polishing;

6. A batch storage system which can reserve 12,000 tons of prepared clay material;

7. Imported molding machines of vacuum extrusion from Italy.

Dry Hanging Terracotta Panel Project View:

Dalian Maternal And Child Health Care Hospital

Previous :

LOPO Classical Red Terracotta Panel System LOPO Classical Red Terracotta Panel System

LOPO Classical Red Terracotta Panel System

External Dark Grey Terracotta Panel Wall Facade

External Dark Grey Terracotta Panel Wall Facade

Lightweight Terracotta Wall Panel for Cladding Decoration

Lightweight Terracotta Wall Panel for Cladding Decoration

Unglazed Natural Clay Terracotta Rainscreen Panel

Unglazed Natural Clay Terracotta Rainscreen Panel

18mm Hollow Structure Terracotta Facade Panel

18mm Hollow Structure Terracotta Facade Panel

Large Supplying Plain Terracotta Cladding Panel

Large Supplying Plain Terracotta Cladding Panel

Never Fade Terracotta Panel Cladding for Exterior

Never Fade Terracotta Panel Cladding for Exterior

Customized Design Available Facade Terracotta Panels System

Customized Design Available Facade Terracotta Panels System