In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

More| *Model No.: | WR852 |

|---|---|

| *Place Of Origin: | China |

| *Material: | Clay |

| *Size: | 240*88*25mm |

| *Color: | Yellow |

| *Packaging Details: | carton with pallet |

| *Payment Terms: | TT; L/C; PayPal; Western Union |

| *Port: | Xiamen Port |

| *Delivery Time: | in 35 days |

| *Certification: | CE, ISO |

Thin Exterior Wall Terracotta Brick Facade

Terracotta brick facade in terms of functionality is similar to ceramic tiles. But since the split brick dovetail back is better than ceramic tiles. With this special back grooves, the clay tiles is very difficult to fall off from the wall.

SPECIFICATIONS:

Size: 240*88*25mm

Requirement Per Square Meter: 43 PCS

Usage: Interior And Exterior Walls

Package: 42PCS/CTN; 19.5KG/CTN

Recommendation: spacer between two tiles (10mm~12mm)

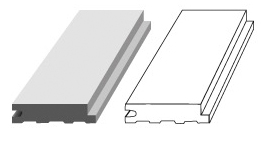

Tile Outline Drawing:

Production Procedure:

Terracotta Tiles' raw material is natural clay, feldspar, sand etc. After natural drying, the raw material is pulverized into powder. The materials will be put into extrusion machine after adding an appropriate water. The wet tiles need to put natural environment for drying about 3 days, then 1.5 days in drying kiln. And 1.5 days in firing kiln. After that, the tiles will be delivered

to split line, in there one tile will be split into two pieces. Final procedure is packing.

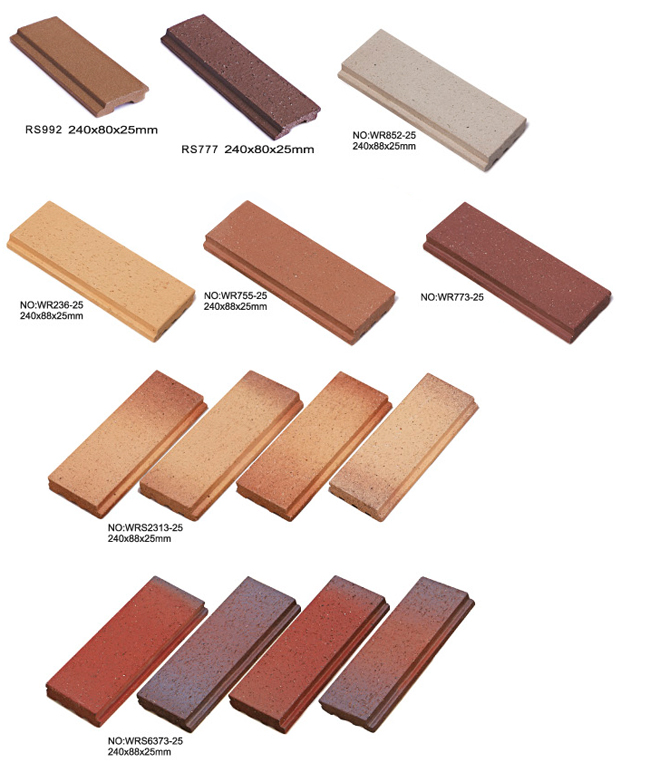

Other Items of Thin Bricks

Company Characteristics:

1.Specialized in clay building material production for more than 15 years. Main stuffs has experience in this area for more than twenty years.

2.LOPO has got the biggest raw material stock yard in Asia, stock quantity about 100 thousand tons. Stable production is ensured.

3.Three production lines can work at the same time. Daily output is about 12000 square meters, which can meet lead time and quantity of different customers.

4.Using No. 0 diesel oil as fuel, which ensure the qualified quantity stable.

5. Imported Germany extrusion equipment, size control become easier.

6.Strong ODM ability, LOPO is the first one to produce reduction burning tiles, metallic color tiles, sand surface tiles, Germany Hamburg Brick, handmade tiles.

7.Emphasize on quality, our products are widely used in typical projects. And were spoken highly by customers

8.Lawful operation, keep sustainable development.

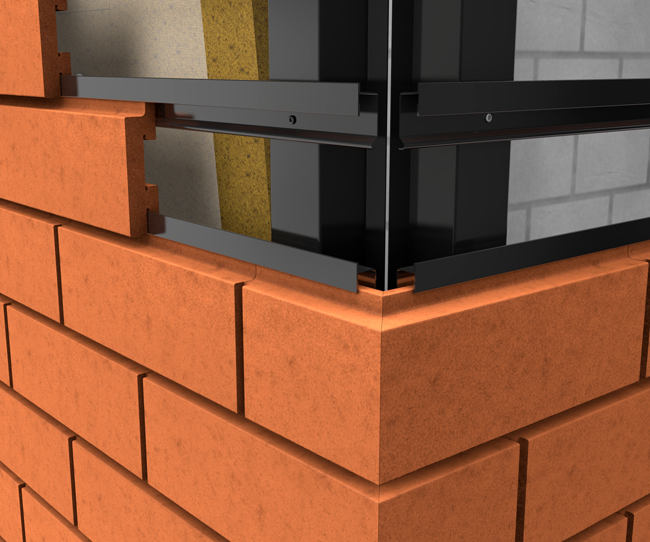

Installation method:

Extremely Rough Surface Wire Cut Red Color Wall Tile

Extremely Rough Surface Wire Cut Red Color Wall Tile

Anti-Frozen Terracotta Cladding Wall Tiles

Anti-Frozen Terracotta Cladding Wall Tiles

Travertine Surface Clay Wall Cladding

Travertine Surface Clay Wall Cladding

Sand Scrash Brick Veneer Yellow

Sand Scrash Brick Veneer Yellow

CE Standard White Color Terracotta Tiles

CE Standard White Color Terracotta Tiles

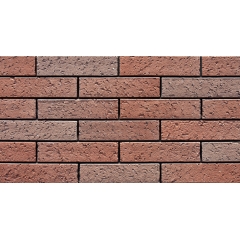

Mixed Color Old Brick Tile

Mixed Color Old Brick Tile

Reduction Buring Travertine Outdoor Tiles

Reduction Buring Travertine Outdoor Tiles

Metal Color Reduction Fired Wall Panel

Metal Color Reduction Fired Wall Panel