In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

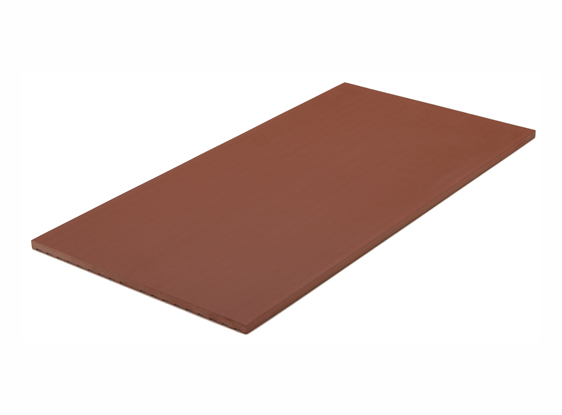

More| *Model No.: | L301268 |

|---|---|

| *Place Of Origin: | Fujian, China |

| *Material: | Natural Clay |

| *Size: | 300*600*12mm |

| *Color: | Red |

| *Packaging Details: | Wooden Crate |

| *Payment Terms: | L/C, T/T, Western Union |

| *Port: | Xiamen |

| *Delivery Time: | 25 days after receiving deposit |

| *Certification: | CE, ISO9001:2006 |

RED EXTERIOR TERRACOTTA FACADE TILE

The color of the Terracotta facade tile has been determined by the clay qualities and without any dyes and thus it is contain the natural colors which is not easy to be faded. The brightness of the color of the terracotta facade could be changed with natural light and weather from the outside world.

DESCRIPTION

Terracotta wall cladding panel have developed into patented proprietary systems from prototypes within the last ten years. Over that time the sizes of terracotta facade tiles have increased and fixing systems have developed for use as solar shading screens to glazed walls as part of an overall rainscreen system for a building facade.

KEY BENEFITS

- Natural terracotta clay materials, eco-friendly

- wide range of sizes and colors available

- Hollow structure and light weight design

- No-static and no-radiation

- Never fade, strong, excellent long-term durability

- Convenient fixing system, safe and reliable

- Extreme UV and weather resistance

- Wind and earthquake resistance

- Anti-fire, anti-freeze, heat preservation and sound insulation- Self-cleaning, low maintenance

EXTERIOR TERRACOTTA FACADE COLOR RANGE

SIZES AND AVAILABILITY

| Regular Product | Color: White/Yellow/Grey/red/Brown Surface Treatment: Flat/Grooved/Sanded/Glazed/Strip-line/Wood Grain/Corrugated |

| Dry Hanging Terracotta Panel | Length: 250-1500mm Width: 150-600mm Thickness: 18mm or 30mm |

| Small Size Terracotta Panel | Width: 100-200mm Thickness: 10-15mm |

| Light Weight Terracotta Panel | Length: 250-1500mm Width: 150-600mm Thickness: 10-15mm |

| Note: | Customized is welcome! Just send us your design or sample. |

APPLICATION:

Municipal Building / Theaters / Education Building /Commercial Building/ Hospital/ Hotel / Airport / Subway/ Residential Area / Renovation of Antique Building etc.

TERRACOTTA FACADE TEST REPORT:

CHARACTERISTIC |

LOPO Specification |

Reference Standard |

Dimensions and Surface Quality |

||

Length |

±1%/max.(L:±1mm; W:±1.5mm) |

ISO10545-2 |

Thickness |

±10%/max.±1.0mm |

|

Straightness of Sides |

±0.5%/max.(L:±2mm; W:±0.5mm) |

|

Rectangularity |

±0.5%/max.±2mm |

|

Surface Flatness(curvature and warpage) |

±1%/max.±2.5mm |

|

Centre |

±1%/max.±2.5mm |

|

Side |

±1%/max.±2.5mm |

|

Warpage |

/ |

|

Surface Quality |

||

Crack |

0 |

ISO10545-2 |

Scratch |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. |

|

Color Difference |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. |

|

Stains |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. Number permitted≤3 |

|

Striation |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is laid flat |

|

Chipped Edge(Length/Width/Thickness) |

Front: max.(w≤1mm, T≤1mm, L≤3mm); Back: max.(w≤2mm, T≤1mm, L≤5mm); |

|

Chipped Corner(Length/Thickness) |

Front: max.(T≤2mm, L≤2mm); Back: max.(T≤2mm, L≤4mm); |

|

Physical Properties |

||

Water Absorption |

Average: E≤6%; Individual max. Value: E≤6% |

ISO10545-3/AS 4459.3 |

Density |

2.3--2.4g/cm³ |

ISO10545-3/AS 4459.3 |

Dry Weight |

31kg/m2(T18mm) |

|

Compressive Strength |

Average 81.4MPa and 11.8psi(Vertical Coring) |

ASTM C126-3 |

Impact Resistance (Coefficient of restitution) |

0.47 |

AS 4459.5 |

Modules of Rupture |

Average 14.5MPa |

AS 4459.4 |

Breaking Strength |

/ |

/ |

Thickness≤18mm |

Average≥2700N; Individual max.value≥2100N |

ISO10545-4 |

18mm |

Average≥5400N; Individual max.value≥4500N |

ISO10545-4 |

Frost Resistance |

No visible damages after 25 changes of freezing and thawing |

ISO10545-12 |

Resistance to Thermal Shock |

Free from defects after 10 cycles |

ISO10545-9/AS 4459.9 |

Thermal Conductivity |

||

Thickness≤18mm |

≤0.35w/(m . k) |

ISO10545-8 |

18mm |

≤0.47w/(m . k) |

|

Moisture Expansion |

0.007% |

ISO10545-10 |

Wind Load |

9Kpa |

ASTM E330 |

Linear Thermal Expansion |

5.46x10ˉ⁶Cˉ¹ |

ISO10545-8 |

Chemical Properties |

||

Resistance to Low Concentrations of Acids and Alkalis |

Not Lower than the requirements of ULB |

ISO10545-13 |

Previous :

LOPO Terracotta Curtain Wall PanelNext :

Natural Solid Grey Terracotta Wall Cladding Panel Small Size Terracotta Wall Tiles

Small Size Terracotta Wall Tiles

Building Wall Clay Terracotta Tiles

Building Wall Clay Terracotta Tiles

Exterior Wall Terracotta Clay Tile

Exterior Wall Terracotta Clay Tile

Unglazed Yellow Terracotta Exterior Tiles

Unglazed Yellow Terracotta Exterior Tiles

Light Weight External Terracotta Clay Wall Panel

Light Weight External Terracotta Clay Wall Panel

Natural Solid Grey Terracotta Wall Cladding Panel

Natural Solid Grey Terracotta Wall Cladding Panel

LOPO Terracotta Curtain Wall Panel

LOPO Terracotta Curtain Wall Panel

Solid LOPO China Terractotta Facade Panel

Solid LOPO China Terractotta Facade Panel