In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

More| *Model No.: | T3090023 |

|---|---|

| *Place Of Origin: | Fujian, China |

| *Material: | Porcelain |

| *Size: | 300*900*18mm |

| *Color: | MIX |

| *Packaging Details: | Wooden Crate |

| *Payment Terms: | L/C, T/T, Western Union |

| *Port: | Xiamen |

| *Delivery Time: | 35 Days |

| *Certification: | CE, ISO9001:2008 |

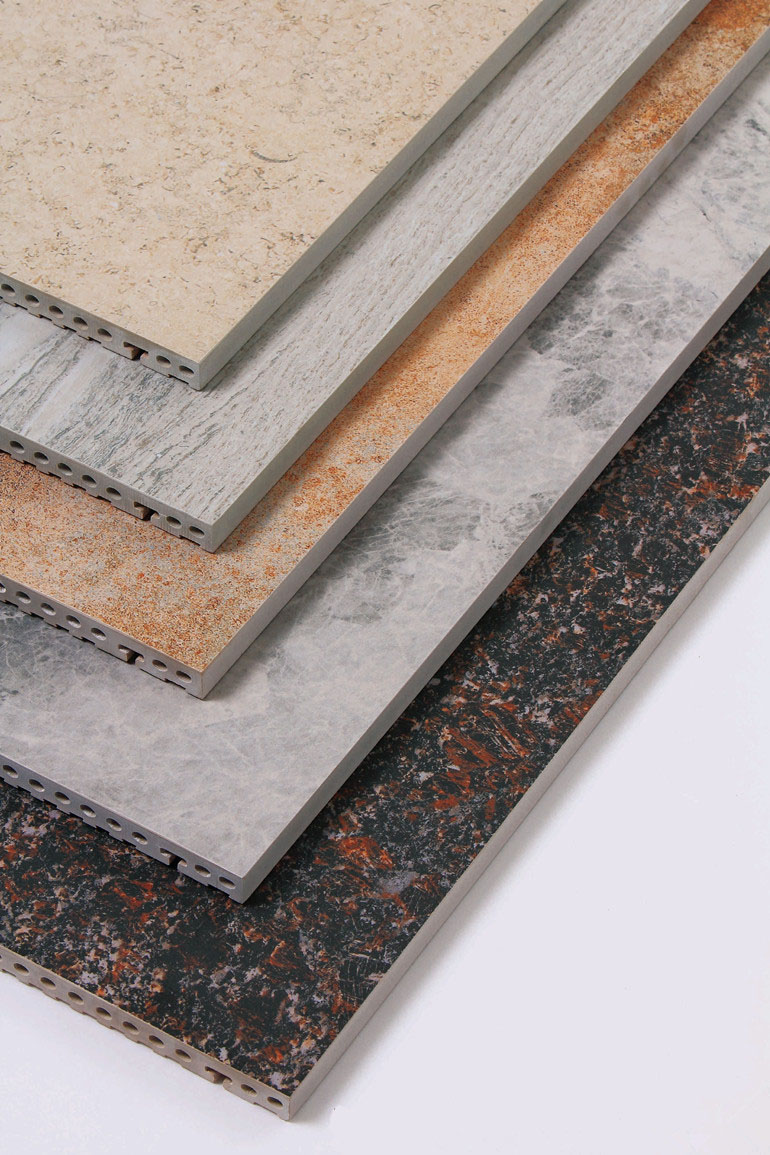

Porcelain tiles have been used for centuries as an exterior cladding material. Marble porcelain cladding panel has all the traditional benefits of a porcelain tile, but in a very large panel of 300x900mm with 18mm thick - which makes it suitable for a new applications such as a cladding material.

SOUND INSULATION EXTERIOR WALL MARBLE PORCELAIN CLADDING PANEL

SPECIFICATION

ITEM NO.

T3010023

SIZE

300x900mm

COLOR

MIX

SURFACE FINISH

3D Inkjet

MATERIAL

Porcelain

WEIGHT

31kgs/sqm

WATER ABSORPTION

Less than 0.5%

THICKNESS

18mm

MOQ

1500sqm

LEAD TIME

35days

INTRODUCTION

Unique inkjet technology transfer the graceful goog looks of granite marble, petrified wood, sandstone etc natural surface into terracotta panel, which enbles consumers to have more choices.

APPLICATION

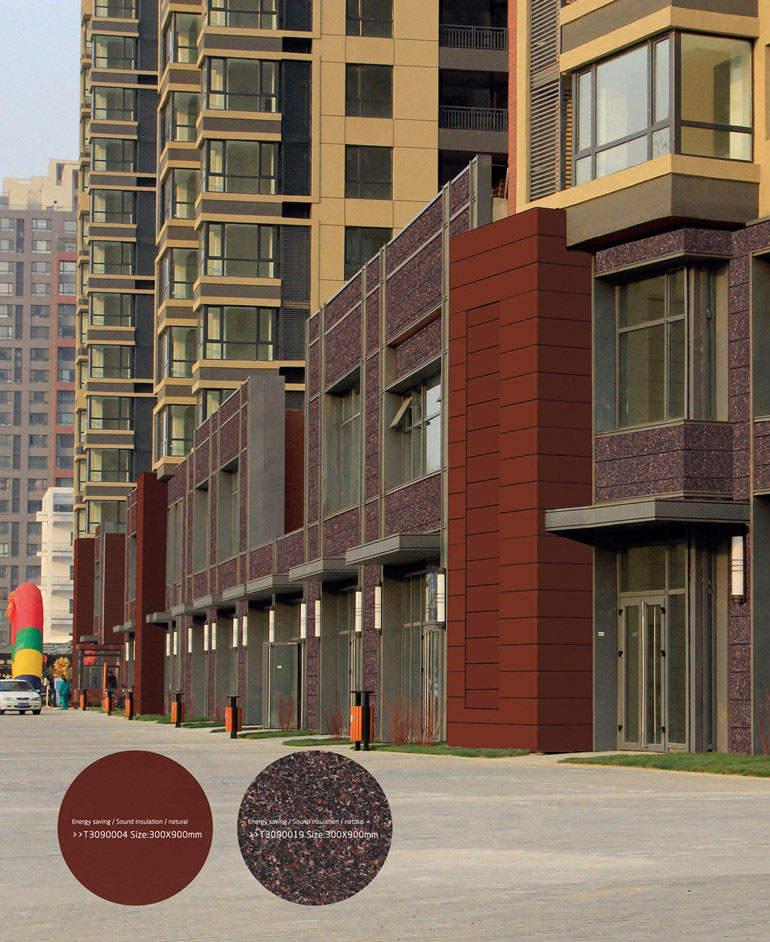

1. Outdoor systems: exterior walls of new buildings or renovated projects

2. Metro system, railway station, tunnel and other underground projects.

3. European / American style architectures, high-end villa walls or roofs

4. High quality requirement ceiling

5. Large public construction projects such as, office building, commercial podium, etc

6. Interior decoration wall system

7. High environmental requirement places such as surgery room, clean room, pharmaceutical and food production workshop wall, etc.

PROJECT

CERTIFICATION

ABOUT LOPO

Lopo was found in 2002, began with specializing in clay brick tiles. Now it owns two industrial parks, one is devoted in clay brick and artificial cultured stone, the other one is focusing on terracotta panel and louver. The total area of industrial parks is more than 540 hectare with total investment more than 3 hundred million.

Lopo is equippeed with the international advanced production line, including the longest roller kiln with automatic temperature control in China, the annual output reached 1.5 million square meters.

80,000 square meter open stockyard with the daily reserve of natural clay raw material amounts to 300,000 tons is the foundation of production and imported molding machines of vacuum extrusion from Italian BONGIOUNNI are the guarantee of qualified products. Domestic longest roller kiln (260 meters) with 428 firing units keeps our terracotta panel's water

Previous :

Engineered Facade Systems Rainscreen Cladding Porcelain PanelNext :

300x900mm Energy Saving Granit Ceramic Wall Panel Exterior Wall Decorative Marble Look Porcelain Panel

Exterior Wall Decorative Marble Look Porcelain Panel

3D Inkjet Ceramic External Wall Panel

3D Inkjet Ceramic External Wall Panel

3D Inkjet Marble Texture Ceramic Terracotta Panel

3D Inkjet Marble Texture Ceramic Terracotta Panel

Petrified Wood Wall Facade Ceramic Wood Panel

Petrified Wood Wall Facade Ceramic Wood Panel

3D Inkjet Wall Cladding Ceramic Facade Panel

3D Inkjet Wall Cladding Ceramic Facade Panel

Antique Ceramic Stone Curtain Wall System

Antique Ceramic Stone Curtain Wall System

Unique Inkjet Technology Dry Hanging Wall Decorative Ceramic Panel

Unique Inkjet Technology Dry Hanging Wall Decorative Ceramic Panel

Natural Surface Exterior Wall Sandstone Ceramic Cladding Panel

Natural Surface Exterior Wall Sandstone Ceramic Cladding Panel