In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

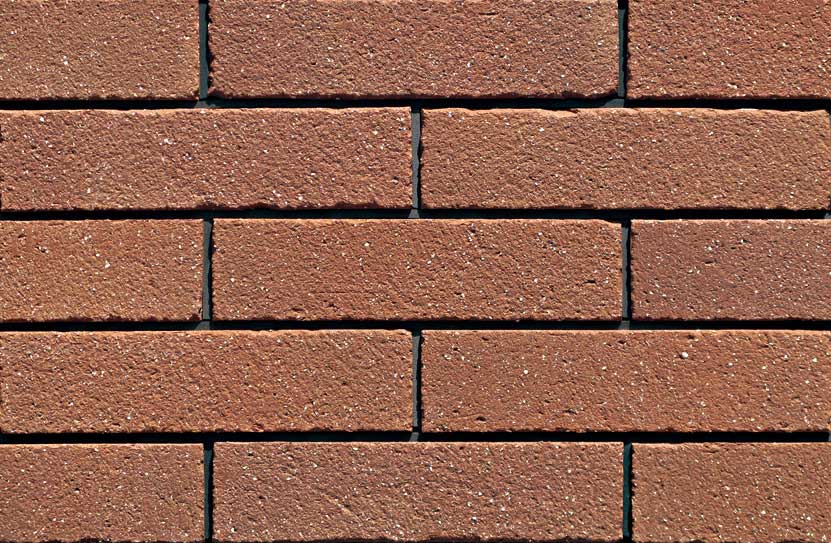

More| *Model No.: | WH755 |

|---|---|

| *Place Of Origin: | China |

| *Material: | Clay |

| *Size: | 230*52*11mm |

| *Color: | Brown |

| *Packaging Details: | carton with pallet |

| *Payment Terms: | TT; L/C; PayPal; Western Union |

| *Port: | Xiamen Port |

| *Delivery Time: | in 35 days |

| *Certification: | CE, ISO |

For Wall From the original of matt finish antique terracotta brick we can know that this kind of tile is made from a certain percentage of different sintering degree clay, different colors and a small amount of mountain flour.

SPECIFICATIONS:

ITEM NO. |

WH755 |

|

SURFACE |

SAND SURFACE |

|

WEIGHT |

19.5kg/CTN |

|

PACKAGE |

FLAT TILE: 70PCS/CTN CORNER TILE: 17PCS/CTN WINDOW TILE: 20PCS/CTN |

|

SIZE AVAILABLE |

FLAT TILE: 230*52*11MM/ 240*60*11MM/ 200*52*11MM CORNER TILE: (168+50)*52MM/ (168+50)*60MM WINDOW TILE: (52+52)*230MM/ (60+60)*240MM |

|

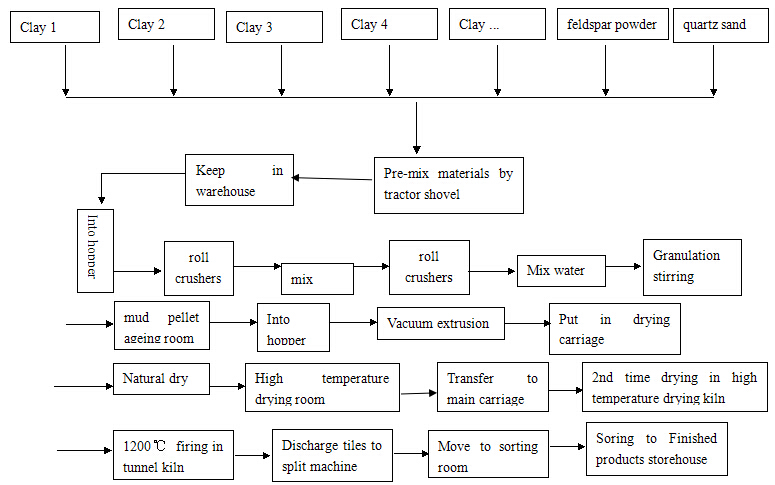

PRODUCTION PROCEDURE:

Natural red terracotta tiles' raw material is natural clay, feldspar, sand etc. After natural drying, the raw material is pulverized into

powder. The materials will be put into extrusion machine after adding an appropriate water. The wet tiles need to put

natural environment for drying about 3 days, then 1.5 days in drying kiln. And 1.5 days in firing kiln. After that, the tiles

will be delivered to split line, in there one tile will be split into two pieces. Final procedure is packing.

TECHNICAL DATA:

Testing Items National Standard Length Difference of average size and working size of a single tile +/-1.5 Width Difference of average size and working size of ten tiles +/-1.5 Thickness Difference of average size and working size of a single tile +/-1.0 Appearance Quality The defects can't be seen in one meter Water Absorption (E,%) 3.0<average E<=6.0 Breaking Mould (R, Mpa) average value R>=13 Fracture Strength (S, N) S>=800 Thermal shock resistance After 10 times testing, No crackle or crack

maximal: +/- 2mm

single value<=6.5

single value>=11

ECO FRIENDLY FACTS

1. All terracotta tile raw material is coming from natural environment. Recycling enable to make full use of all materials and make sure zero wastage..

2. Production scheduled in off-peak periods so as to reduce the national electricity pressure..

3. Energy to bake our clay products are natural gas, which will not leak out harmful element to environment. It is cleaner and safer if compared with coal and oil.

4. The movement of terracotta tiles are in rails on the floor. Forklifts working energy can be saved.

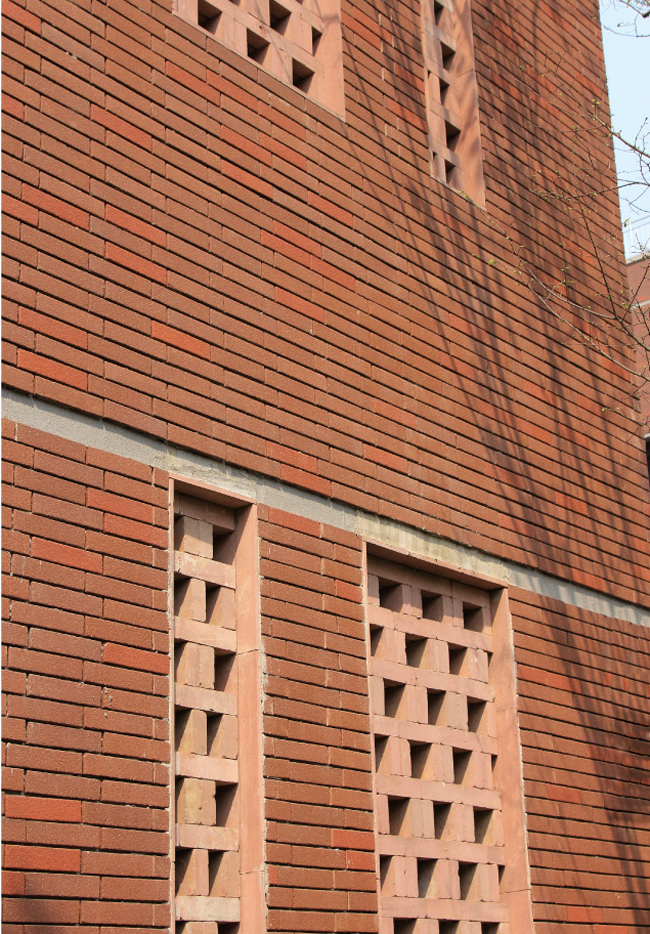

PROJECT PICTURE:

Previous :

Red Clinker With Black Sand Surface Tile Wall PanelsNext :

Red Color With White Sand Matting Terracotta Wall Tiles Extremely Rough Surface Wire Cut Red Color Wall Tile

Extremely Rough Surface Wire Cut Red Color Wall Tile

Anti-Frozen Terracotta Cladding Wall Tiles

Anti-Frozen Terracotta Cladding Wall Tiles

Travertine Surface Clay Wall Cladding

Travertine Surface Clay Wall Cladding

Sand Scrash Brick Veneer Yellow

Sand Scrash Brick Veneer Yellow

CE Standard White Color Terracotta Tiles

CE Standard White Color Terracotta Tiles

Mixed Color Old Brick Tile

Mixed Color Old Brick Tile

Reduction Buring Travertine Outdoor Tiles

Reduction Buring Travertine Outdoor Tiles

Metal Color Reduction Fired Wall Panel

Metal Color Reduction Fired Wall Panel