In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

MoreThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

MoreNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

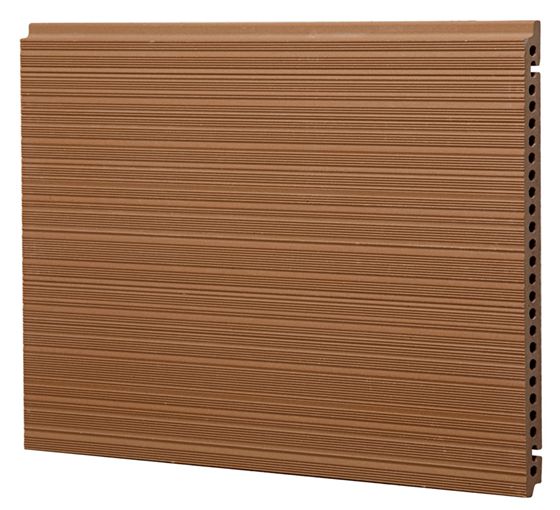

More| *Model No.: | FX3518572 |

|---|---|

| *Place Of Origin: | Fujian, China |

| *Material: | Natural Clay |

| *Size: | 300*600*18mm |

| *Color: | Red |

| *Packaging Details: | Wooden Crate |

| *Payment Terms: | L/C, T/T, Western Union |

| *Port: | Xiamen |

| *Delivery Time: | 25 days after receiving deposit |

| *Certification: | CE, ISO9001:2008 |

Composite terracotta cladding systems are quickly and easily installed onto aluminum support profiles with Joint Inserts, assuring consistent and uniform vertical and horizontal alignment.

EXTERIOR BUILDING COMPOSITE TERRACOTTA CLADDING SYSTEMS

APPLICATION:

Municipal Building / Theaters / Education Building /Commercial Building/ Hospital/ Hotel / Airport / Subway/ Residential Area / Renovation of Antique Building etc.

ADVANTAGES:

1. Never Fade

Terracotta panel made up from high quality natural pure argil, via vacuum high pressure extrusion molding, burn out from high temperature. With low consumption and no radiation, light pollution, never fade and can effectively resist ultraviolet radiation, durable, 100% of the repeatable recycling. It’s environmental protection material choice.

2. Waterproof & Insulation Sound Noise

Terracotta panel cavity design greatly reduces the materials self weight, reduce building façade structure system load, meanwhile, after high temperature firing, can effectively reduce the heat transfer coefficient, make ceramic plate with greater intensity, makes its enhanced against the bad weather, the waterproof is admirable.

3. Anti Fire &Freeze

Advanced technology and equipment, precise cutting, strict calibrated to ensure the product quality and size stability. Terracotta panel a has good security anti fire characteristics, anti acid and alkali corrosion resistant, anti scratch and abrasion. Even face supernormal low or high temperatures, it could keep stable.

4. Rain Self-cleaning

Clay materials content metal very low, do not produce electrostatic, not easy to absorb dust, dirt not easy deposition, via wind and rain could self cleaning.

5. Simple Natural

The Terracotta panel colors is rich, covers the modern architecture mainstream color design requirements. Natural texture and external clay color collect architectures rich artistic style.

6. Diversity Styles and Sizes

LOPO offers a variety styles and sizes for your chosen, its complete sizes through different product combination and cutting to meet designer’s style requirement.

TERRACOTTA CLADDING SYSTEMS FIXING COMPONENTS:

TERRACOTTA PANEL TEST REPORT:

CHARACTERISTIC |

LOPO Specification |

Reference Standard |

Dimensions and Surface Quality |

||

Length |

±1%/max.(L:±1mm; W:±1.5mm) |

ISO10545-2 |

Thickness |

±10%/max.±1.0mm |

|

Straightness of Sides |

±0.5%/max.(L:±2mm; W:±0.5mm) |

|

Rectangularity |

±0.5%/max.±2mm |

|

Surface Flatness(curvature and warpage) |

±1%/max.±2.5mm |

|

Centre |

±1%/max.±2.5mm |

|

Side |

±1%/max.±2.5mm |

|

Warpage |

/ |

|

Surface Quality |

||

Crack |

0 |

ISO10545-2 |

Scratch |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. |

|

Color Difference |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. |

|

Stains |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is hanging vertically. Number permitted≤3 |

|

Striation |

No obvious flaw is visually inspected from a distance of 1.5metres while the tile is laid flat |

|

Chipped Edge(Length/Width/Thickness) |

Front: max.(w≤1mm, T≤1mm, L≤3mm); Back: max.(w≤2mm, T≤1mm, L≤5mm); |

|

Chipped Corner(Length/Thickness) |

Front: max.(T≤2mm, L≤2mm); Back: max.(T≤2mm, L≤4mm); |

|

Physical Properties |

||

Water Absorption |

Average: E≤6%; Individual max. Value: E≤6% |

ISO10545-3/AS 4459.3 |

Density |

2.3--2.4g/cm³ |

ISO10545-3/AS 4459.3 |

Dry Weight |

31kg/m2(T18mm) |

|

Compressive Strength |

Average 81.4MPa and 11.8psi(Vertical Coring) |

ASTM C126-3 |

Impact Resistance (Coefficient of restitution) |

0.47 |

AS 4459.5 |

Modules of Rupture |

Average 14.5MPa |

AS 4459.4 |

Breaking Strength |

/ |

/ |

Thickness≤18mm |

Average≥2700N; Individual max.value≥2100N |

ISO10545-4 |

18mm |

Average≥5400N; Individual max.value≥4500N |

ISO10545-4 |

Frost Resistance |

No visible damages after 25 changes of freezing and thawing |

ISO10545-12 |

Resistance to Thermal Shock |

Free from defects after 10 cycles |

ISO10545-9/AS 4459.9 |

Thermal Conductivity |

||

Thickness≤18mm |

≤0.35w/(m . k) |

ISO10545-8 |

18mm |

≤0.47w/(m . k) |

|

Moisture Expansion |

0.007% |

ISO10545-10 |

Wind Load |

9Kpa |

ASTM E330 |

Linear Thermal Expansion |

5.46x10ˉ⁶Cˉ¹ |

ISO10545-8 |

Chemical Properties |

||

Resistance to Low Concentrations of Acids and Alkalis |

Not Lower than the requirements of ULB |

ISO10545-13 |

Previous :

LOPO Self Cleaning Glazed Terracotta Exterior Wall PanelsNext :

Outside Facade Green Ceramic Terracotta Wall Panel 18mm Exterior Wall Dry Hanging Terracotta Panel

18mm Exterior Wall Dry Hanging Terracotta Panel

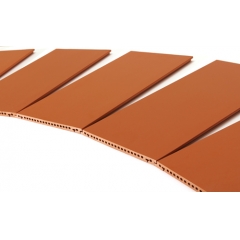

LOPO Classical Red Terracotta Panel System

LOPO Classical Red Terracotta Panel System

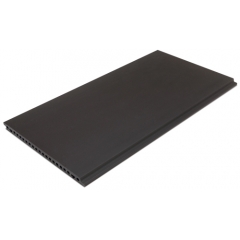

External Dark Grey Terracotta Panel Wall Facade

External Dark Grey Terracotta Panel Wall Facade

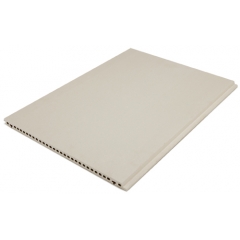

Lightweight Terracotta Wall Panel for Cladding Decoration

Lightweight Terracotta Wall Panel for Cladding Decoration

Unglazed Natural Clay Terracotta Rainscreen Panel

Unglazed Natural Clay Terracotta Rainscreen Panel

18mm Hollow Structure Terracotta Facade Panel

18mm Hollow Structure Terracotta Facade Panel

Large Supplying Plain Terracotta Cladding Panel

Large Supplying Plain Terracotta Cladding Panel

Never Fade Terracotta Panel Cladding for Exterior

Never Fade Terracotta Panel Cladding for Exterior